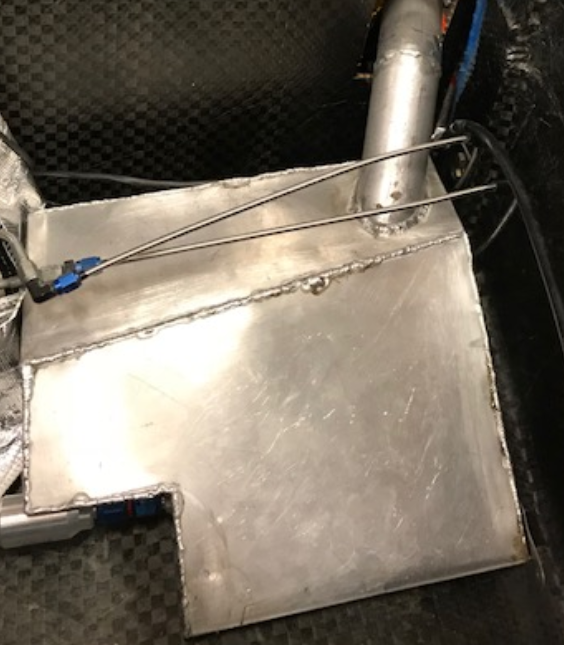

Motorsports Aluminum Fuel Tank

Numerical simulations, design, and full fabrication of the fuel tank

For the Illini Motorsports Formula SAE team I designed and fabricated our aluminum fuel tank. There were several constraints and considerations which guided the design. First and foremost, was driver safety. The fuel tank had to be packaged in such a way that any malfunction could not put the driver at risk. Additional packaging constraints required that the fuel tank had to compactly fit in it’s assigned area. In addition, serviceability was a key consideration in that the fuel tank needed to be easily accessed in the event of failures such as fuel pressure drops.

Beyond high-level qualitative measurements, fuel tank design also required consideration of the effects of fuel slosh and the weight of the tank. A thin aluminum sheet was selected to reduce weight while still ensuring the tank could be made without leaks.

Fuel slosh has the potential to cause dynamic fuel starvation issues and impact vehicle dynamics. To reduce fuel slosh internal baffling was used. To determine an effective baffling design I set up computational fluid dynamics situations which used inertial loads recorded during real racing events and observed the fuel slosh caused during different baffle designs. The effects of baffling could be measured by the amount of time that fuel was present at the designed outlet and the net kinetic energy of the fuel.

With both the internal and external geometries designed, I made the fabrication drawings, waterjet all of the sheet parts, hand-bent all sheet metal into it’s final shape, profiled the tubes for the filler neck of the tank, and welded the entire assembly. The fuel tank was then leak-tested under pressure to ensure that it would be safe under operating conditions.

In retrospect, I cared a little too much about making it lightweight and used overly thin aluminum - I think it was 18 gauge. Since the tank needed to be fully leak-free, the thin aluminum stock resulted in a much longer welding time than was maybe worth it for the relative weight savings. Time may have been better spent focusing on other components, performing testing, or helping move the car towards being test-ready on other components.